Programming by Tweezer

In another post I mentioned that one summer I wrote the firmware for a couple of Commodore’s calculators. Commodore had a wide variety of proprietary calculator chips that they used for an even wider range of calculators. The earliest example I can think of is what I think was Commodore’s first calculator that had only one chip. Prior to this there were two chips. One that did the computations and one that provided the drive current for the LED display. I won’t go into the details but a clever engineer figured out how to get the computation chip to also drive the LEDs. it required a pretty basic change to the way the display subsystem worked but wouldn’t make the calculation chip more complex. This was code named RBP (Rock Bottom Price). The designer was sure that the chips would be opened to figure out how this was done so he added the letters FKU to a corner of the die. I used to have a few of these actual chips but I can’t find them.

The chips used in the calculators I wrote the code for were named GHU (God Help Us) after my father’s warning after approving the idea: “God help you if this doesn’t work”. This was a two (or more) chip set. One, GHU-1, was a generic calculator processor and display driver. The others were one or more ROMs (Read Only Memory) that allowed a large number of models to differ only by the ROM(s) being used.

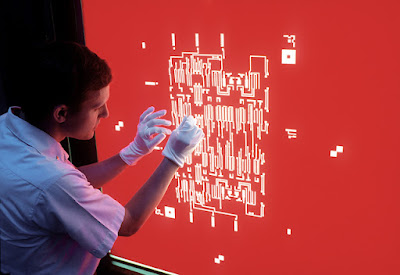

Both of these chips were made in the era where essentially all such design work was done by hand. Chips are made by intricate mechanical and chemical processes that built all of the circuit elements in layers. These were drawn, by hand, using drafting systems onto large transparent sheets of plastic that, for the chips in the GHU system, were a few feet across. These were then, layer by layer, converted to a pattern of red and clear plastic known as rubylith. A two layer combination of clear plastic with a very thin red layer that could be cut loose and removed to form the patterns. Here’s a picture of a small example.

These patterns are called masks and were photo reduced to the actual size of the chip.

The GHU-2 ROM had a mask layer where each bit of the ROM was precut and it was programmed by using a tweezer to remove a small rectangle, a couple millimeters on a side, of the red film. I remember spending a LONG time, hunched over a light table, with a plot of all of the bits of red film that needed to be removed. Above this plot was the mask layer and, after VERY carefully aligning the layers, I removed the indicated bits of red plastic. At the time it seemed almost like magic.